Furnace Burner Management System

Project Summary:- Supply, Design, Engineering, Testing, commissioning of Burners, combustion fan, related burner valves and equipment's, PT and DPT transmitters and Allen Bradley Logix platform PLC & Training of System.

Objective:-

- Disinvest the existing set of Burners, Burner Management System, Controls and replace with New Burners along with its Control System.

- To achieve the Melt Rate of 10T/hr.

- Reducing the inventory cost by utilising the same equipment's as installed in other Furnaces.

- To avoid frequent failures and disruption in production.

- To reduce the Maintenance Cost.

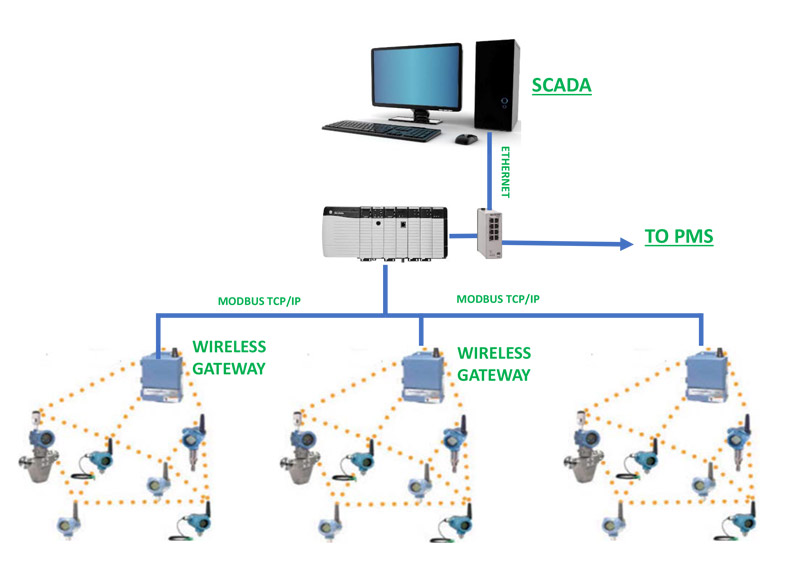

- Transfer of critical Burner Data to MES/ SCADA for further Analysis and Reporting.